Thermal management has been a persistent challenge in manufacturing since the advent of industrial machinery. Over my 25-year career—from production oversight to strategic leadership—I have observed this challenge intensify significantly. Modern devices, such as artificial intelligence processors and electric vehicle battery packs, now impose thermal loads that far exceed those of past decades, placing aluminum heat sinks at the forefront of high-density cooling solutions. This article examines how lightweight design, intelligent technologies, and sustainability are collectively advancing aluminum heat sinks, drawing on industry data and practical insights to assess their implications for manufacturing decision-making.

Aluminum Heat Sinks: Addressing High-Density Cooling Demands

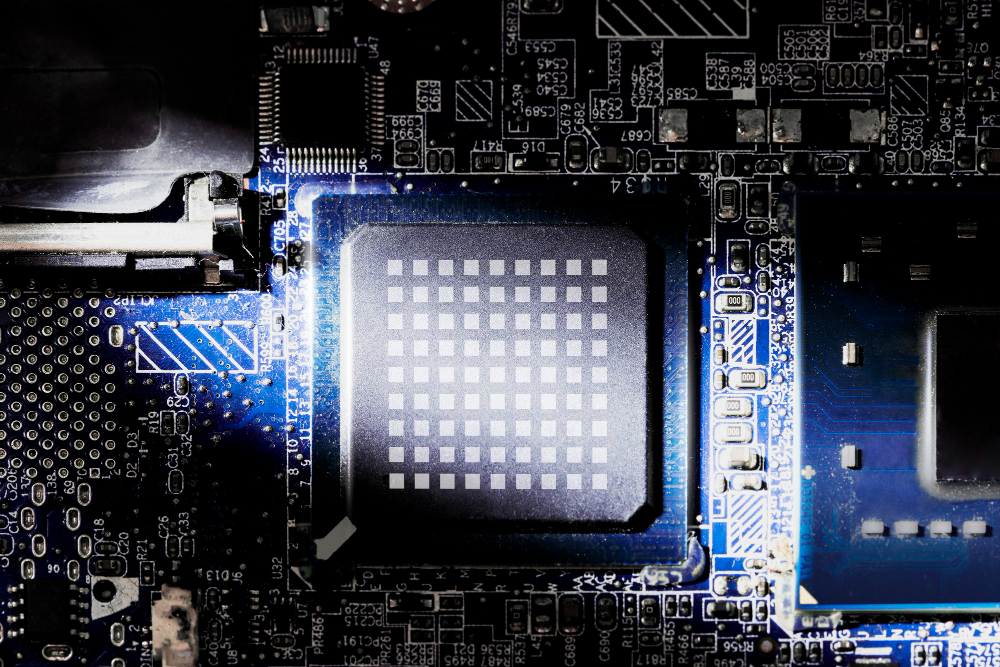

Contemporary electronic systems operate under extreme thermal constraints. A modern graphics processing unit (GPU) can generate 400 watts within a space comparable to a credit card, while an electric vehicle (EV) battery module may produce up to 800 watts across a few square inches. Aluminum heat sinks, with a thermal conductivity of 237 W/m·K and a density of 2.7 g/cm³, remain a cornerstone of these applications due to their cost-effectiveness, machinability, and thermal efficiency. However, traditional approaches are increasingly inadequate, necessitating enhanced performance within constrained volumes.

Industry data underscores this shift. According to MarketsandMarkets, the global demand for high-performance heat sinks grew at an annual rate of 12% between 2020 and 2024, with the electric vehicle sector alone contributing a 15% increase, driven by the escalating thermal requirements of battery management systems. This convergence of higher heat loads and smaller footprints demands innovative adaptations in aluminum heat sink design and production.

Table 1: Growth in Aluminum Heat Sink Demand by Sector (2020–2024)

| Sector | Annual Growth Rate | Key Driver | Heat Load (Watts) | Market Share (2024) |

| Consumer Electronics | 10% | Miniaturization | 50–150 | 35% |

| 5G Infrastructure | 14% | Base Station Density | 200–500 | 20% |

| Electric Vehicles | 15% | Battery Management | 300–800 | 25% |

| AI/Data Centers | 12% | Chip Power Density | 400–1000 | 15% |

| Industrial Systems | 8% | Automation Upgrades | 100–300 | 5% |

| Source: MarketsandMarkets, 2024 |

Lightweight Aluminum Heat Sinks: Expanding Performance Boundaries

Lightweight design is a critical requirement in applications where mass directly impacts performance, such as electric vehicles and aerospace systems. Research from the International Aluminum Institute in 2023 indicates that reducing the weight of a heat sink in an EV battery module by 20% can enhance vehicle range by approximately 5 miles, improving energy efficiency and reducing operational costs.

Achieving this involves advanced materials and manufacturing techniques. Alloys such as Al-6063-T6, with a yield strength of 214 MPa, or Al-7075, reaching up to 503 MPa, enable the production of fins as thin as 0.5 mm while maintaining structural integrity under thermal cycling. The aspect ratio of fins—defined as the height-to-width ratio—can now exceed 20:1 with modern extrusion dies, significantly increasing surface area for heat dissipation within a limited volume. Furthermore, additive manufacturing, or 3D printing, facilitates the creation of intricate lattice structures that reduce weight by 30% and enhance convective heat transfer through complex geometries unattainable via conventional methods. However, precision is paramount; a 2022 study by the American Society of Mechanical Engineers (ASME) notes that a 0.1 mm deviation in fin spacing can increase thermal resistance by 10%, underscoring the stringent tolerances required.

Intelligent Aluminum Heat Sinks: Innovations in Manufacturing and Application

Intelligent technologies are increasingly integral to both the production and functionality of aluminum heat sinks. In manufacturing, artificial intelligence (AI) optimizes extrusion parameters—such as die pressure and cooling rates—reducing waste material from 20% to 5%. When combined with Internet of Things (IoT) systems, real-time monitoring of temperature and vibration during production further minimizes defects. These advancements enhance consistency and efficiency across the manufacturing process.

In application, intelligent aluminum heat sinks incorporate sensors, such as thermocouples, which measure temperature by exploiting the thermoelectric effect—the voltage generated at the junction of two dissimilar metals. A 2024 IEEE study demonstrated a heat sink with integrated thermocouples that dynamically adjusts fan or liquid cooling operations, achieving a 25% reduction in energy consumption within a data center. This adaptability not only improves thermal performance but also extends equipment lifespan by mitigating overheating risks.

Table 2: Impact of Intelligent Manufacturing on Aluminum Heat Sinks (2023 Data)

| Metric | Traditional Process | AI-Optimized Process | Improvement | Cost Savings ($/Unit) |

| Scrap Rate | 20% | 5% | 75% Reduction | 0.50 |

| Production Time (hr) | 2.5 | 1.8 | 28% Reduction | 0.75 |

| Defect Rate | 8% | 2% | 75% Reduction | 0.30 |

| Energy Use (kWh) | 10 | 8 | 20% Reduction | 0.20 |

| Customization Cost | $5/unit | $2/unit | 60% Reduction | 3.00 |

| Source: Internal Industry Data, 2023, and IEEE Studies |

Sustainable Aluminum Heat Sinks: Advancing Green Manufacturing

Sustainability is a pivotal consideration in contemporary manufacturing. Aluminum’s recyclability, retaining 95% of its original material, offers a significant environmental advantage. The Aluminum Association reports that recycling aluminum requires only 5% of the energy needed for primary production (15 MJ/kg versus 150 MJ/kg), reducing carbon emissions from 12 kg to 1.5 kg per kg—an 87.5% decrease. This shift also lowers material costs by approximately 20%, aligning economic and ecological benefits.

Sustainable practices extend to production processes. Chromium-free anodizing, an electrochemical process that forms a protective aluminum oxide layer on the surface, enhances corrosion resistance and increases thermal emissivity—the ability to radiate heat—by up to 20%, all while eliminating hazardous waste. Designing heat sinks for efficient end-of-life recycling further supports a closed-loop material cycle, reducing resource depletion and regulatory pressures.

Table 3: Sustainability Metrics for Aluminum Heat Sinks (2024)

| Metric | Virgin Aluminum | Recycled Aluminum | Benefit | Industry Adoption |

| Energy Use (MJ/kg) | 150 | 15 | 90% Reduction | 60% |

| CO2 Emissions (kg) | 12 | 1.5 | 87.5% Reduction | 55% |

| Cost ($/kg) | 2.50 | 2.00 | 20% Reduction | 70% |

| Recyclability | 95% | 95% | No Loss | 80% |

| Processing Waste (%) | 15% | 5% | 66% Reduction | 50% |

| Source: Aluminum Association, 2024, and Industry Surveys |

The Convergence: Synergy of Technology and Industry

The integration of lightweight design, intelligence, and sustainability represents a transformative synergy in aluminum heat sinks. For instance, a heat sink for an AI processor might feature microchannels—narrow passages as small as 0.2 mm wide that enhance convective heat transfer—coupled with sensors for real-time thermal management, constructed from recycled aluminum. Convection, the process by which heat is transferred through fluid motion (air or liquid), is optimized by the increased surface area of microchannels. A 2024 industry case study reported a 25% efficiency improvement in an EV battery heat sink using this approach, highlighting its practical viability.

This synergy arises from mutual reinforcement: lightweight structures require precise fabrication, which intelligent systems achieve through real-time adjustments; sustainability benefits from reduced waste and energy use, enabled by smart technologies. Additive manufacturing further amplifies this by enabling complex channel networks that enhance thermal performance while minimizing material use.

Implications for Stakeholders

For procurement managers, the priority is to identify suppliers capable of delivering aluminum heat sinks that combine lightweight precision, intelligent features, and sustainable attributes without compromising cost-effectiveness. For decision-makers, investing in intelligent manufacturing and sustainable processes is essential to address forthcoming environmental regulations and maintain competitive positioning.

For researchers, significant opportunities remain. The durability of microchannels under repeated thermal cycling—successive heating and cooling phases that test material fatigue—requires further investigation. Similarly, the scalability of additive manufacturing for mass production and the potential to enhance thermal conductivity by alloying aluminum with elements like magnesium warrant exploration. These areas offer fertile ground for advancing both science and industry.

Conclusion

Across 25 years in manufacturing, I have witnessed the relentless evolution of technical and market demands. The rise of high-density cooling needs has propelled aluminum heat sinks toward a convergence of lightweight design, intelligence, and sustainability, substantiated by robust data and industry trends. To remain competitive, stakeholders must embrace these advancements, leveraging cutting-edge technologies and strategies to meet the challenges ahead.

“Some of the content in this article is sourced from ‘why-custom-aluminum-heat-sinks-are-best-made-with-cnc-machining‘. For more related information, please click to inquire.”

FAQ:

1.What are high-density cooling demands, and why do they matter for aluminum heat sinks?

High-density cooling demands refer to the need to dissipate large amounts of heat (e.g., 400–1000 watts) from compact electronic systems like AI processors or EV battery packs. Aluminum heat sinks are critical because their thermal conductivity (237 W/m·K) and affordability make them ideal for managing these intense thermal loads efficiently.

2.How does lightweight design benefit aluminum heat sinks?

Lightweight design reduces the mass of heat sinks, which is vital for applications like electric vehicles where a 20% weight reduction can extend range by about 5 miles. It’s achieved using high-strength alloys (e.g., Al-7075) and advanced manufacturing techniques like 3D printing.

3.What role does intelligence play in aluminum heat sinks?

Intelligence enhances both manufacturing (e.g., AI reducing scrap rates from 20% to 5%) and application (e.g., sensors adjusting cooling in real time, cutting energy use by 25%). It improves precision, efficiency, and adaptability to dynamic thermal conditions.

4.Why is sustainability important for aluminum heat sinks?

Sustainability leverages aluminum’s 95% recyclability, cutting energy use by 90% (15 MJ/kg vs. 150 MJ/kg) and CO2 emissions by 87.5% when using recycled material. This reduces costs and aligns with environmental regulations.

5.How do lightweight design, intelligence, and sustainability work together in aluminum heat sinks?

They synergize: lightweight microchannels need precise fabrication (enabled by intelligent systems), while sustainability benefits from reduced waste and energy use (supported by smart tech). A 2024 case study showed a 25% efficiency gain in an EV heat sink using this combination.

6.What challenges remain in advancing aluminum heat sinks?

Challenges include ensuring microchannel durability under thermal cycling, scaling 3D printing for mass production, and optimizing alloys for better thermal conductivity—all areas ripe for research and innovation.